Liquid Cooling Plates

The Future of Efficient Thermal Management.

JARO’s Liquid Cooling Plate is an efficient cooling solution widely used in electronic devices, data centers, and high-performance computing, among other fields. It absorbs and dissipates heat generated during device operation by circulating coolant, thereby maintaining the optimal operating temperature of the equipment. The working principle of the liquid cooling plate relies on the high thermal conductivity of the liquid (such as water or coolant), swiftly conducting heat to the coolant through precisely designed channels, and then removing the heat through the cooling system.

The Advantages of Liquid Cooling Plates Compared to air cooling systems

- Higher heat dissipation efficiency:

- Effective handling of applications with high heat flux density.

- Ensures stable operation even under heavy loads.

- Compact structure

- Occupies minimal space, making it suitable for environments with limited space constraints.

- Lower noise levels:

- Operates with reduced noise levels, contributing to creating quieter work environments.

These advantages contribute to enhancing equipment performance and reliability, leading to the increasing adoption of liquid cooling plate technology across various industries and applications.

Types of Liquid Cooling Plates

Classified by Production Process

Friction Stir Welding (FSW) Cooling Plates

Friction Stir Welding Cooling Plate is a cooling device manufactured using Friction Stir Welding (FSW) technology. Friction stir welding (FSW) is a welding process where a cylindrical called a welding pin is inserted into the joint of the workpieces. Through the high-speed rotation of the welding head, the tool generates friction with the material of the workpieces, causing the material at the joint to heat up and soften. Bonding it under pressure to form high-strength welds.

Key Features

- High-Strength Welding:

Friction Stir Welding technology enables high-strength welding without melting the materials, resulting in superior welding quality compared to traditional methods. - Defect-Free Welds:

Since the welding process is conducted in the solid-state, common welding defects such as porosity and cracks are absent in the weld seam. - Material Compatibility:

Suitable for welding various metal materials, especially aluminum, copper, and other non-ferrous metals.

Vacuum Brazing Cooling Plates

Vacuum Brazing Cooling Plate is a cooling device manufactured using vacuum welding technology. Add solder to the cover and base of the cooling plate and assemble them, then fix them in a vacuum brazing furnace for welding. The solder melts at high temperatures and flows into the gap between the cover and base plate, forming a strong bond.

Key Features

- Efficient Heat Dissipation:

The vacuum brazing cooling plate is designed with intricate internal channel structures, allowing the coolant to rapidly and effectively absorb heat, thus maintaining stable operation of the equipment. - High Thermal Conductivity:

Utilizing high thermal conductivity metal materials facilitates efficient transfer of heat from the heat source to the cooling medium. - Leak-proof and Durable:

Vacuum brazing technology creates strong, pore-free joints at the connections, ensuring the liquid cooling plate is leak-proof and has a longer lifespan.

Product Display

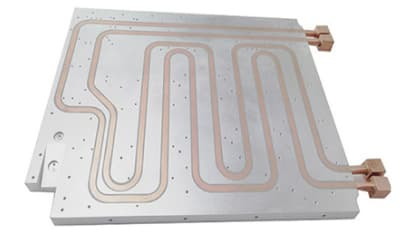

Copper Tube Embedded Cooling Plate

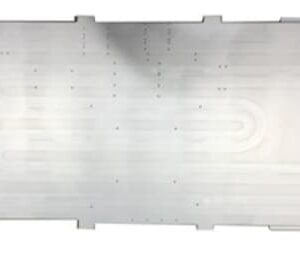

Friction Stir Welding Cooling Plates

Friction Stir Welding Cooling Plates

Friction Welding Cooling Plate

Casing Components

Liquid Cooling Plate

Friction Welding Flow Path

Vacuum Brazing Cooling Plate